precision machining Secrets

The reducing velocity permitted through the slicing Instrument is determined by exactly the same factors since the slicing forces and is particularly associated in a fancy method into the tool’s resistance to dress in (Determine 5).

Quite possibly the most recent statistical solutions are employed to analyze our procedures, assuring the best top quality product or service is produced as well as strong, repeatable production method selected remains steady and unchanged.

These are definitely applied in response to the suspected deviation from one or more on the Basin Excellent Methods. Sources with the deviation may possibly stem from a potential customer problem or criticism, unacceptable levels of merchandise non-conformance, difficulties recognized through an inside audit, or adverse or unstable trends in product and method monitoring as would be determined by statistical course of action Management.

Considerations To Know About precision machining

CNC machining is probably the quickest ways to develop functional prototypes, solution molds, low to significant volume output operates, and fixtures.

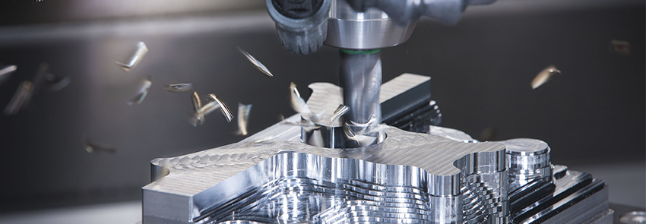

The chip eradicated by the cutting Software (cutter, drill bit, broaching Instrument, or milling cutter) for the duration of machining could be in the shearing, steady, or discontinuous variety, dependant upon the slicing situations. The type of chip development and deformation with the steel is generally analyzed for distinct circumstances, according to the cutting circumstances, and also to the chemical composition and physicochemical Attributes in the steel staying machined, the slicing fee, the geometry of your chopping part of the tool, the orientation of your reducing edges relative to your reducing velocity vector, as well as lubricant-coolant.

Turret mills normally Have got a quill which makes it possible for the milling cutter to generally be elevated and reduced within a method just like a drill push. This type of device provides two methods of reducing while in the vertical (Z) course: by boosting or decreasing the quill, and by relocating the knee.

These devices are operated by specialized and experienced machinists. The precision machining system includes a slicing Instrument that removes substance through the workpiece. To ensure that the cutting Device to perform its task, it should be moved in Instructions specified to make the proper Lower. This Principal motion is called the “cutting velocity.†The workpiece can be moved, often known as the secondary motion of “feed.†Jointly, these motions along with the sharpness on the chopping Instrument enable the precision equipment to operate. Find out more:

Since obtaining a selected machining Heart, NIST has seasoned unacceptable machine conduct for the duration of regional energy activities that have weakened in-system pieces.

Fascination About machining

In 1952, numerical Command achieved the developmental phase of laboratory fact. The first NC device Software was a Cincinnati Hydrotel milling machine retrofitted by using a scratch-designed NC control unit.

A reducing fluid is commonly applied to the machining operation to chill and lubricate the chopping Instrument. Figuring out no matter whether a slicing fluid should be employed, and, If that is so, picking out the good slicing fluid, is normally incorporated in the scope of chopping ailment.

What exactly is a precision instrument? Precision indicates precision. A precision instrument is full article actually a major quality one which is Tremendous-correct. You will get an instrument that can just do The task, or you'll be able to commit extra cash and acquire a precision instrument that should be ideal. Quite a few measuring gadgets are precision instruments as they must be t…otally accurate. (Far more)

The performance of machining relies on the establishment of efficient reducing charges, using all pertinent factors into account. Pcs are made use of to speed up calculations.

Not known Factual Statements About precision machining

Alright, alright here’s a sneak peek of your bullpup right before SHOT. And more importantly, this authentic awesome custom result in we’ve obtained occurring due to Timney Triggers and our linkage.